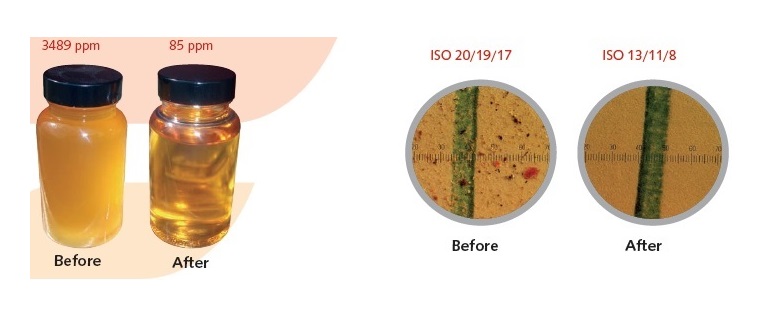

As much as 80% of the failures of lubricating and hydraulic systems are caused by contamination with solids and water. Even if no direct machinery failures are identified, a high contamination level greatly decreases the efficiency of a machine.

Any substance which is extraneous to the system and adverse to its performance parameters can be considered a contaminant. Contamination can take the form of gas, liquid, or solid matter. Particulate contamination comes in all shapes and sizes, and very often has abrasive properties. The high level of contamination accelerates the wear of components and reduces their lifetime. Worn components make the system work less efficiently, make parts wear quicker, increase the temperature of fluids, cause leaks and the loss of control over the operation of the entire system.

All these phenomena are a direct result of the mechanical interaction of contaminants with system components. Contamination can also act as a catalyst accelerating the oxidation of fluid and stimulate the chemical breakdown of its components.

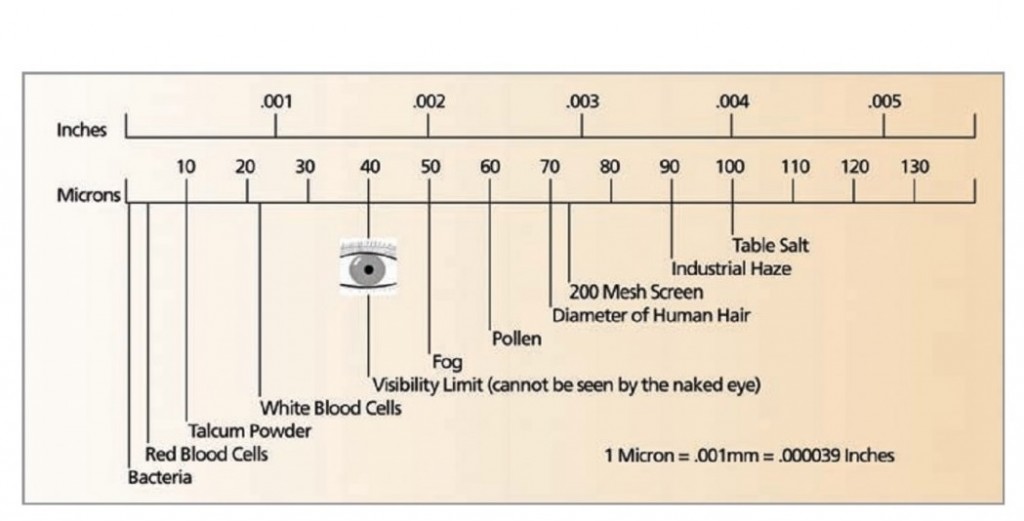

The table below illustrates the inability of the human eye to see below 40 microns, i.e. the microscopic and harmful particles in oil, fuel and liquids, which are invisible to humans. Particles of 5 microns act as sandpaper and gradually destroy system components.